Whether you call it a sugar shack or the maple bush, eastern Canadian kids have been loaded onto big yellow school buses for decades destined for what was always one of the favourite field trips of the year. It’s almost impossible to go wrong with a school day spent roaming around in the forest just as the snow is starting to melt, watching sap flow from trees and of course eating pancakes with real maple syrup!

After spending a few years living in Alberta where Maple trees (and therefore sugar shacks) are almost non-existent, when we moved back to Ontario I couldn’t wait to sign my name up as a parent volunteer for the annual maple syrup field trip. Except, for reasons that are completely lost on me, the school stopped bussing kids out to the maple bush and instead signing up as a parent volunteer means flipping pancakes made from a mix for hundreds of kids in the school gym.

I’m all for pancakes, but this is not the truly Canadian maple syrup experience I want my children to grow up having.

When searching out Ontario sugar shacks for our next #CanadaWithKids adventure, we decided to go big – the biggest in fact! We were destined for Gilbertson’s Maple Products, located on St. Joseph’s Island in Northern Ontario just 40 minutes from Sault Ste. Marie, Ontario. Gilbertson’s is Ontario’s largest producer of maple syrup and is a 4th generation family business established in 1936.

To get onto St. Joe’s, we crossed the Bernt Gilbertson St. Joseph Island Bridge (yes – the bridge is named after the founder of Gilbertson’s Maple Products). As we drove down the country roads I noticed the bush was filled with blue plastic pipes. Everywhere you looked you saw trees linked by a sea of blue.

“What is that?” I asked my grandma who had joined us for the trip (trips are always better with Grandma!) who proceeded to tell me that this was how they took sap from the trees. I knew immediately this was not going to be the sugar shack I remembered from my grade-school days.

What I expected to see was literally a shack in the woods surrounded by trees with buckets like this one which is visible from Gilbertson’s as you walk through the bush…

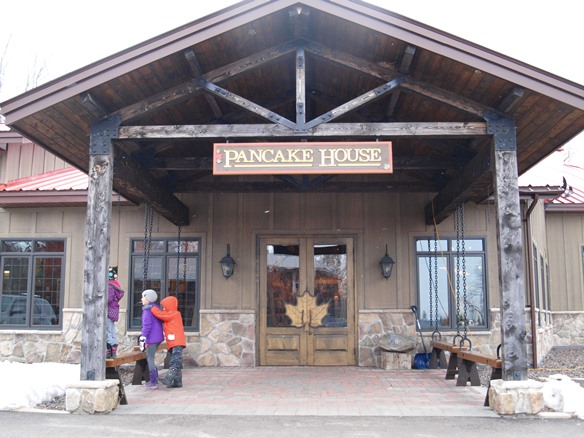

Instead, we pulled up to a beautiful stone and wood beam building.

First stop – pancakes! It was lunch time and we were starving.

Grandma and I drank maple coffee and the kids sipped on maple tea with a bit of maple sugar and coloured pictures while we waited for our pancakes. I was forewarned that the pancakes were huge so we ordered three meals for our table of five. It was enough of everything except for the breakfast sausage which my kids devoured so we opted for another side order.

Stuffed with pancakes and Gilbertson’s maple syrup we headed out to the maple bush. You have the option to walk the trail that loops around the part of the bush that is closest to the main building or have a wagon ride. Of course, my kids opted for the tractor-pulled wagon.

Gord was our tractor driver and he was certainly informed. He stopped along the route to point out remnants of the “old days” and to share interesting facts about the maple syrup business and Gilbertson’s.

Then he stopped the tractor and let the kids get out to see the blue lines up close and touch the vacuum suction that brings all the sap from the trees to storage tanks until there is enough sap to begin processing.

We were all amazed to learn that Gilbertson’s taps 45,000 trees over 500 acres every single year! It takes about a dozen workers using hand-held electric drills about four to five days to tap all those trees.

Gord also shared that while Gilbertson’s uses over 200 kms of blue pipelines above ground, they also run more than 40 kms of underground pipeline to transport the sap.

Clearly the blue lines are much more efficient than the bucket system of the past!

After our tractor ride, we headed back into the main building to check out where the sap was processed and learned the efficiencies do not stop at the pipeline!

Gone are the days where the sap is boiled in large cauldrons over a wood fire. Instead, Gilbertson’s uses a reverse osmosis process by pushing the sap through a series of filters to remove over 60% of the water from the sap before it’s boiled. This helps reduce the boiling time which is more environmentally friendly and helps lower production times and cost.

After this, the syrup hits the evaporator for boiling then goes through another series of filters before it is canned or barreled for sale.

So how much sap does it take to make 1 litre of maple syrup? 40 litres of sap is needed for every litre of maple syrup!

We were lucky enough that a Gilbertson family member was onsite in the evaporator room to show us around and share even more maple syrup facts. He also shared with the kids a bit of his family history and even a piece of a tree he keeps on display that still holds a piece of an old-fashioned spile his great grandfather had drilled into the tree by hand.

The evolution of the sugar shack is truly amazing to experience firsthand, but so too was the pride in the business and the commitment to family tradition that was evident in every single part of our trip to Gilbertson’s.

And not to worry! There are still lots of tapped trees with buckets just waiting for kids to stick their fingers under and taste the sap for themselves – just like we did in the “olden days”.

PS: Don’t forget to stop at the gift shop! We came home with maple syrup (of course), maple sugar, maple tea and my favourite maple candies shaped like maple leafs that they make on-site!

For more information about how maple syrup is processed check out Gilbertson’s “From Tree To Table”.